Mike's 'High Peak Tramway' layout was in one of these classrooms, and Mike invited me to 'have a drive'. It was great fun! The copy-and-paste from the group's website below explains what the layout is about, and Mike showed me how to drive trains, change points, and couple and uncouple rolling stock.

High Peak Tramway.Hazel Grove and District Model Railway Society.Scale 7mm/ft 1:43.5 Gauge 16.5mm |

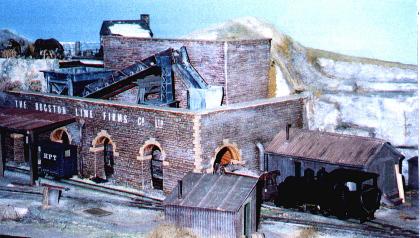

The gauge of this award winning layout is a scale 2ft 4¼in. It is set in the foothills of the Derbyshire Peak District and portrays a line built to transport stone from the quarries to an arm of the Peak Forest Canal. The period is around the 1930s when it would still be very active moving stone, while retaining a passenger and general goods service.

| Nothing comes ready made in this scale/gauge combination so all the locos, rolling stock and buildings have been made from scratch or kits.

The rolling stock is modelled on examples which ran on various Narrow Gauge lines in the UK such as the Glyn Valley and Lynton and Barnstaple Rlys, plus those that were found on the quarry and trench tramways of the First World War.

|

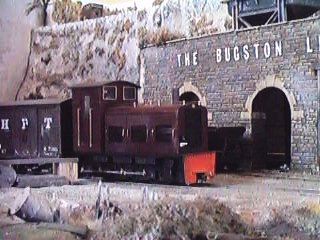

| Bugston Road is the newest part of the layout. Its station building and road over bridge are based on those which still exist at Irton Road on the Ravenglass and Eskdale Railway in the Lake District. Bugston Road also features a small plateway system for horse drawn wagons. We have not as yet produced any horses small enough to make this a working section! |  |

| Some of the buildings of Bugsworth Station are being replaced as they are between 10 and 15 years old. Our policy is one of continuous improvement, as they say in various industries. Wagon loads of stone are represented by small chippings. These are loaded into empty wagons at Bugston Road by a conveyor. The wagons are then transferred to Bugsworth. Here the loads are automatically tippled into a narrow boat in the canal basin (the load actually drops through the baseboard into a receptacle for return to the conveyor). Hence loading and unloading is achieved with out the use of out of scale hands (usually). |

| The whole layout occupies an area of 8’0” by 13’ 3”. However, Bugston Road can be operated separately from the main part of the layout, using a hidden four road sector plate when exhibition or operating space is at a premium. |  |

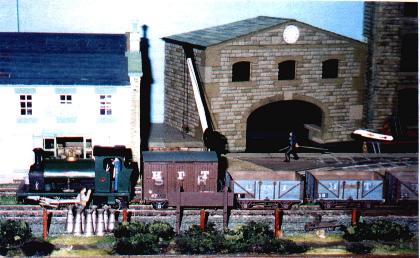

| A scene at Bugsworth station including some of the new buildings. |

| The boss, Mike Hunter, performing some unknown activity. Perhaps he is praying for divine inspiration, or maybe he has managed to super glue his hands together! |

The layout is divided into two operating 'areas', Bugsworth and Bugston Road (the trans-shipment shed at Bugsworth is a copy of the one at Whaley Bridge basin at the end of the Peak Forest Canal). There are two operators, one for each 'area', and each has a small hand-held controller with 'direction of travel' switch and a speed control knob. There are operator panels on the back of the layout facing the operators (who stand in the 'U' shaped space between Bugsworth and Bugston Road on the diagram) which have track plans on them, with switches where each point is (to control the point) and further switches to allocate areas of the layout to the control of either operator. There are also push-buttons to operate small electro-magnets between the rails which can uncouple rolling stock.

So a stone train might be waiting at Bugsworth to go to Bugston Road, and a passenger train to do the reverse trip. The Bugston Road operator will take control of the stone train and drive it to Bugston road, whereupon the Bugsworth operator can take control of the passenger train and drive it to Bugsworth.

When the stone train arrives at Bugsworth Road the loco and brake van are detached. The brake van is parked in a spur, then the loco runs around the train to propel it forward into the stone shed where, one waggon at a time, it is loaded with stone chippings. The train is then withdrawn from the stone shed and propelled forward into the spur to pick up the brake van. The entire train is then ready to be driven back to Bugsworth where the stone will be trans-shipped into a narrow boat on the canal.

Meanwhile, the passenger train at Bugsworth is parked in the platform while the loco runs around ready to make the return journey to Bugsworth Road.

Mike let me take the position of Bugsworth Road operator for a session and it was great fun! The group do have a timetable they run to, but on this occasion we just 'made it up as we went along' with the stone train, the passenger train, and a quarrymans' train.

I thoroughly enjoyed my stint as a 'model train driver' and if Mike and his merry men are ever short of an operator, they know where to find a willing helper!